I selected my warp but not having enough spools of each color do to a direct beaming onto the sectional beam, I had to first measure out the warp for each 2" section of the back beam. Then thread it through the tension box and do the beaming. It took a day to measure the warp for each section (there are 7 sections, 5 of 2" and 2 of 1" on each edge). It took another day, for each section, to set up the tension box and wind it on to the beam. WHEW I spent over 2 months of Saturdays working on this alone. It took another month and a half to just thread the heddles and the reed.

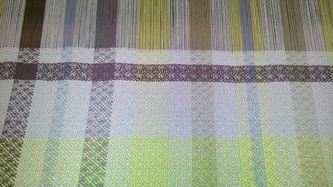

I did not weave at all in September as I went to Scotland, so I finally started to weave in October. And that's when I found I had threading mistakes in the heddles so I had to re-slay a large section of the warp. So I was ready to weave again. Next I realized I had a few dents in the reed that had 4 threads and not 2 (it was a 15 dent reed so at 30 threads per inch, there should only be 2 threads in each slot). After that was corrected, I could finally, finally (re) start weaving.

I wove my 2" hem on the first placemat \0/ and then I found the worst problem yet. Several sections of the warp were twisted and "knotted". I could not really weave because each time that I had to advance the warp, I would have to work the twists backwards to the back beam hoping that I had not broken a thread DAMN! It was now January and I had been working on this warp since July! I was ready to pull it off and throw it away but I really could not. So it sat for all of February as I was away again taking a metal class.

How did this happen?

Well, with the 30 threads per inch, and normally with directly winding the warp onto the back beam, the mini-reed in the tension box keeps the threads aligned and you don't need to use lease sticks to help "maintain the cross" But with so many threads going through the tension box, they were a bit twisted to begin with as they were wound onto the beam. Then when I was threading the heddles, I did not have an exact thread order so as I picked up a thread to put through a heddle, compounded the issue by using them in any order. I was now paying for that error.

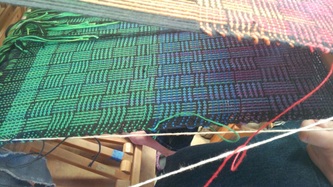

When I returned to the barn at the start of March I decided to wind the entire 16 yard warp on to the front beam while using 4 lease sticks. As I would advance the warp, I would work the twists backwards, and I would have to work them backwards over 16 yards. OY! So I went in to the barn on a Saturday very early and I started my task. When I had finished, at 6 pm, it had taken me 8 hours but I was done, the twisting and knots were out. I went home after that.

Yesterday, after two weeks away, I went back to barn and now it was time to wind it all back onto the back beam. My lease stick were in place and this would help with the tensioning. First I had to even up the warp threads and tie them into a knot for each section, then attach each section to the back beam chords. So inch by inch, I would un-wind about 6 inches from the front beam, then go to the back of the loom and wind it on the back beam making sure the warp threads were of even tension and would lay in the correct section. Then repeat. I started at 10 am and I was done at 3 pm. I tied onto the front beam and I was done, FINALLY.

Next time I am the barn I can really, really, really start weaving, NINE MONTHS LATER.

RSS Feed

RSS Feed