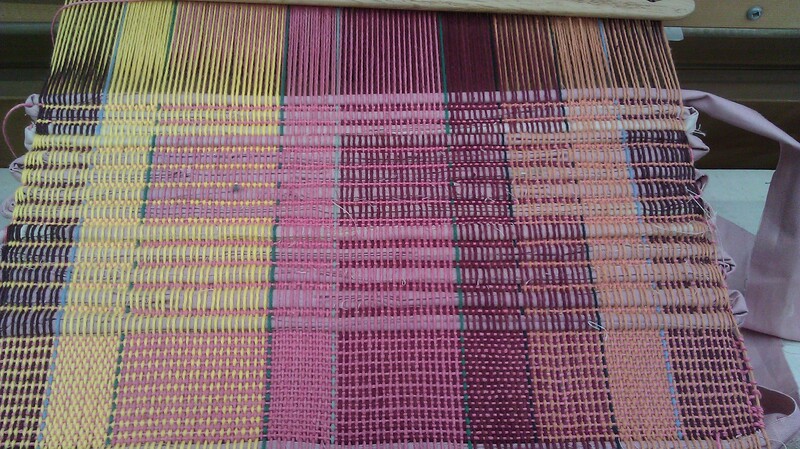

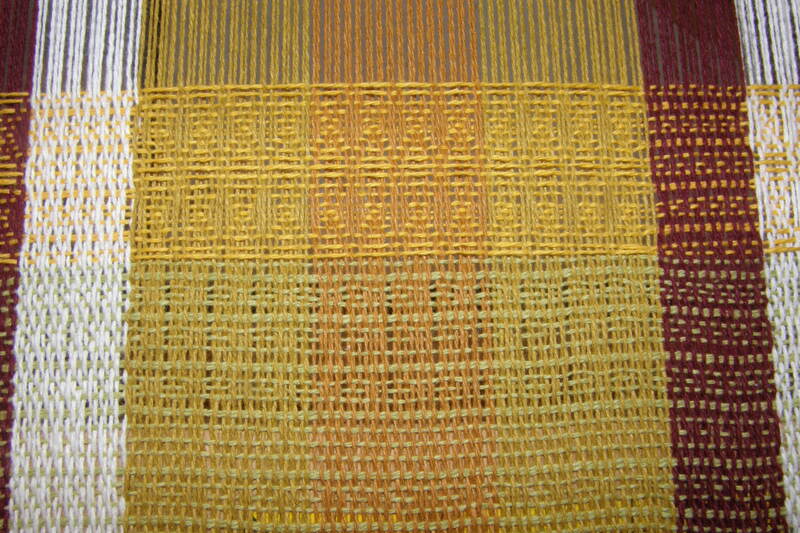

I pulled the left over skeins from knitting projects out and have started to weave up squares for a couch throw.

BUT wait there is more!!

I joined 2 pin loom groups on Facebook. The first is just a general support group and the other is for making a Temperature Blanket. In a nutshell it is Data Visualization as Art - there are all sorts of projects like this; Google it and get lost on the web.

Well, being an engineer who loves data AND being a weather dork who likes to track rain fall I was instantly in.

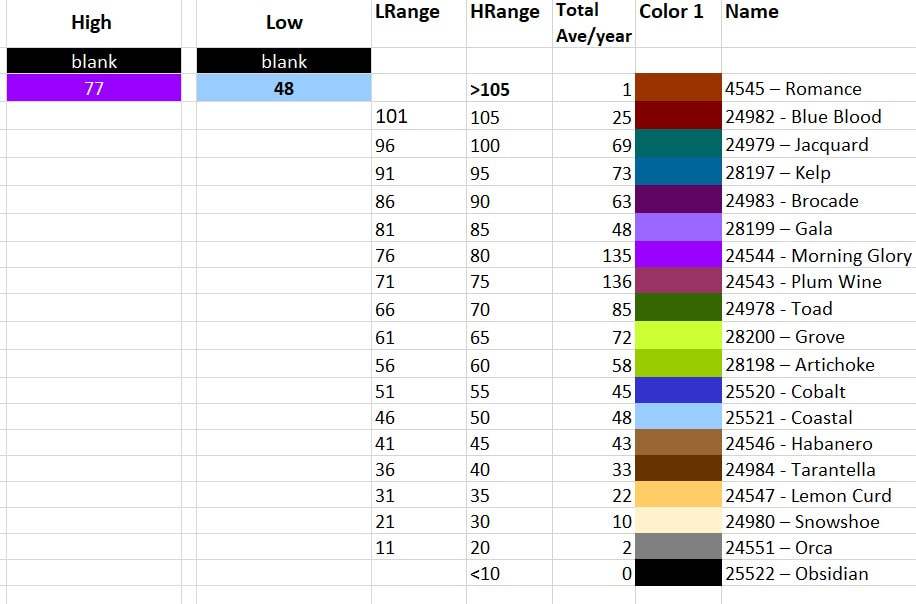

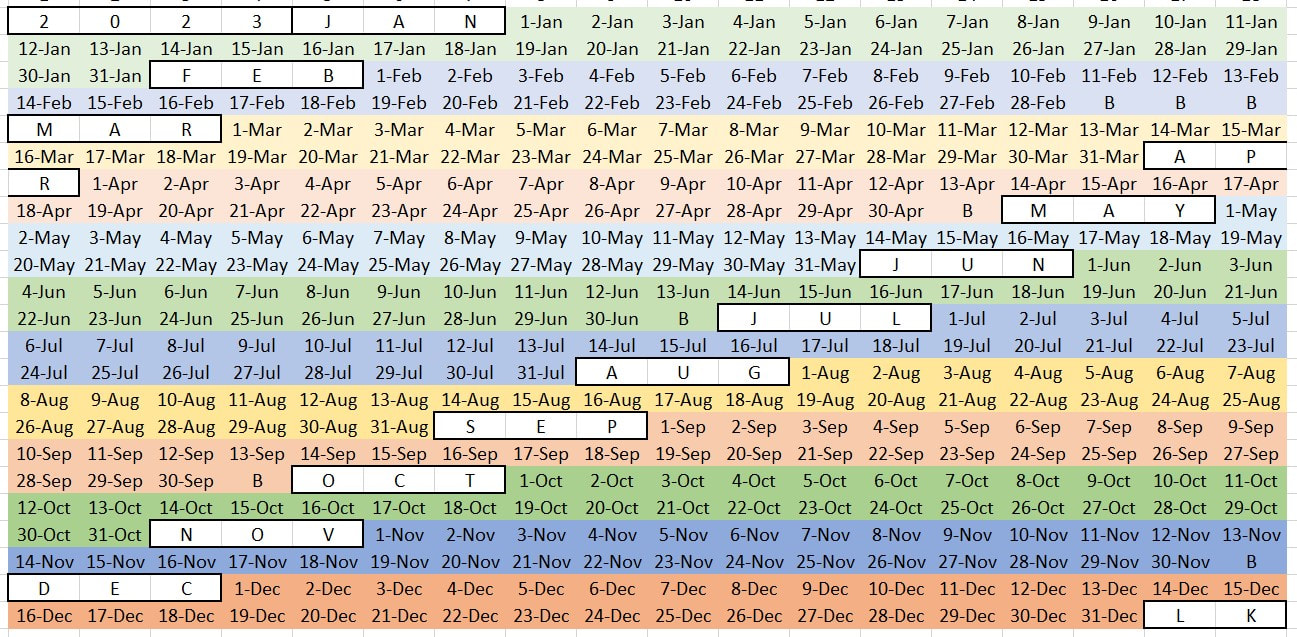

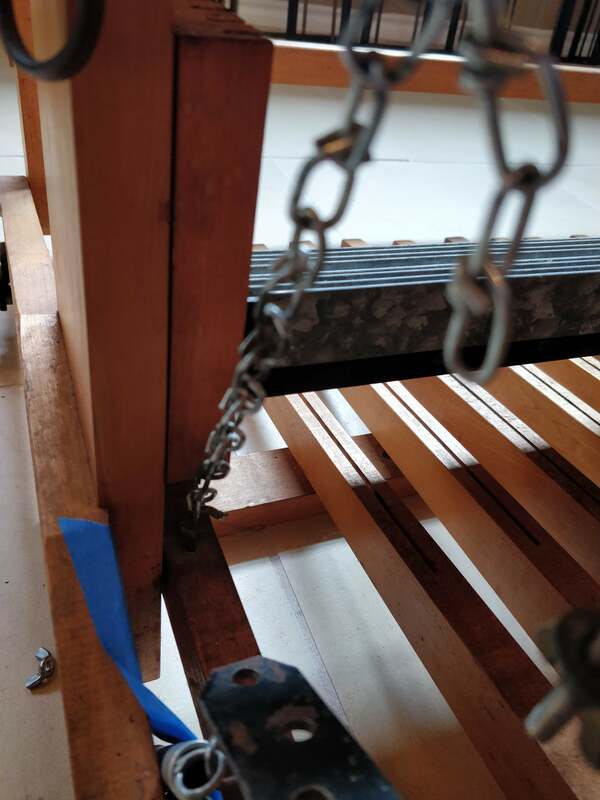

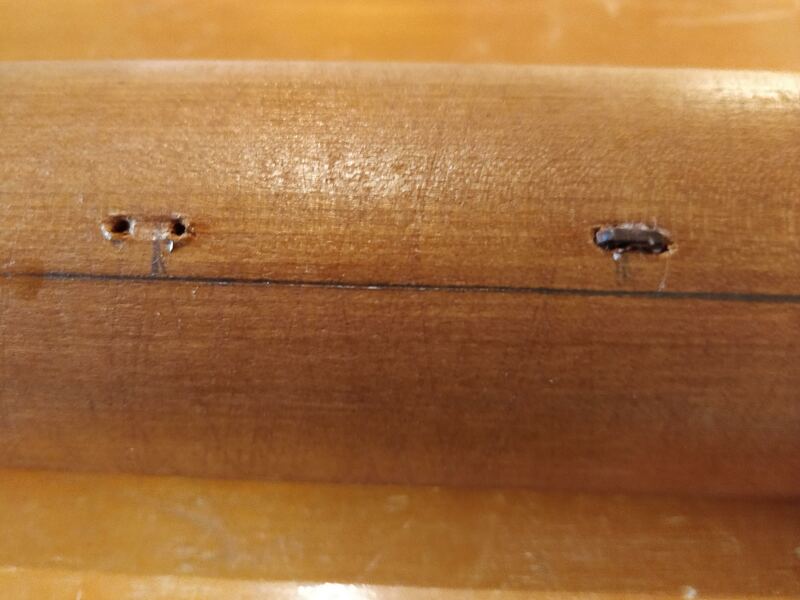

I spent almost a week selecting my yarn and setting up the temperature ranges. I wanted a single color way that had 15+ colors so I could do high and low temps with most temperature bands being 5 degrees. I went with Knit Picks City Tweed DK. Next, I had to select colors for the temperature bands and based upon historical data estimate yardage for each color; then I placed my order for it and it will be here next week. I am going to weave squares with the warp and weft being the high and low temps for the day and rain or snow I will insert a white warp thread for each inch and a weft thread for each 0.1 inch of precipitation. The last task was to figure out the layout and I settled on a modified linear calendar and I will use triangles around the outside.

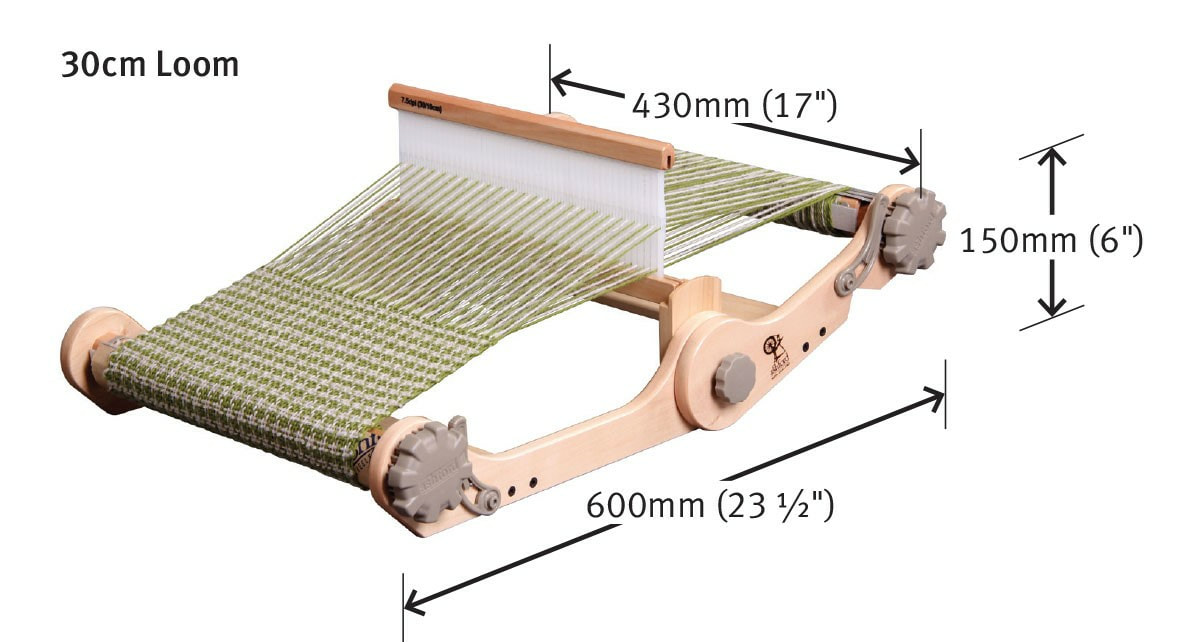

Here are pictures of the yarn colorway, the temperature bands and assigned color(s), and the blanket layout.

RSS Feed

RSS Feed